Composting is the natural process of decomposition and biodegradation. In simple terms, microorganisms break down organic residues into valuable soil amendments such as compost and, over time, stable humus. To keep the process efficient, you need the right balance of nitrogen and carbon, plus adequate moisture and oxygen.

Typically, this process proceeds under aerobic conditions; however, short anaerobic phases can occur when piles compact or get too wet. Managing aeration and moisture is essential, in practice, regular turning and careful layering maintain an optimum microbial environment.

Key Findings

Biokomposter sped things up. The treated windrow matured faster than the control; as a result, compost reached a stable state sooner.

AT4 dropped sharply. The AT4 score (lower = more mature) was about half in the Biokomposter pile; therefore, the compost was more stable by the end of the 20 weeks.

Timing stayed on track. Because the pile matured on schedule, you reduce the risk of spreading immature compost that can hinder growth.

Handling was easier. The material became more uniform; consequently, turning and spreading felt cleaner and more predictable.

Nutrient return was steadier. In turn, growers can plan applications with more confidence for regenerative goals.

Basics still matter. Even so, good aeration and moisture management remain essential for best results.

Real-world setup. Two outdoor windrows (control vs Biokomposter) ran for 20 weeks; meanwhile, AT4 testing tracked maturity and showed the gap.

Bottom line: Biokomposter helps hop residues compost faster and finish cleaner, so you get field-ready compost on time without the usual risks linked to immature material.

Field trial with hop harvest residues

Our researchers evaluated composting performance on hop harvest residues. Specifically, they arranged the material into two windrows (3 m × 5 m × 2 m):

- Control windrow – composted naturally without additives.

- Biokomposter windrow – treated with a microbiological preparation designed to accelerate composting.

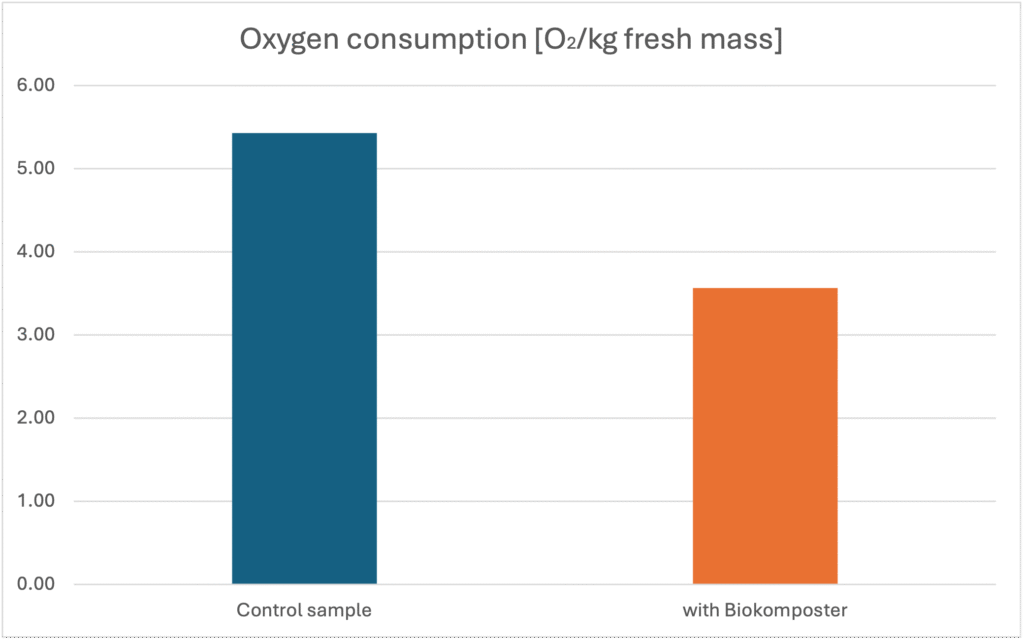

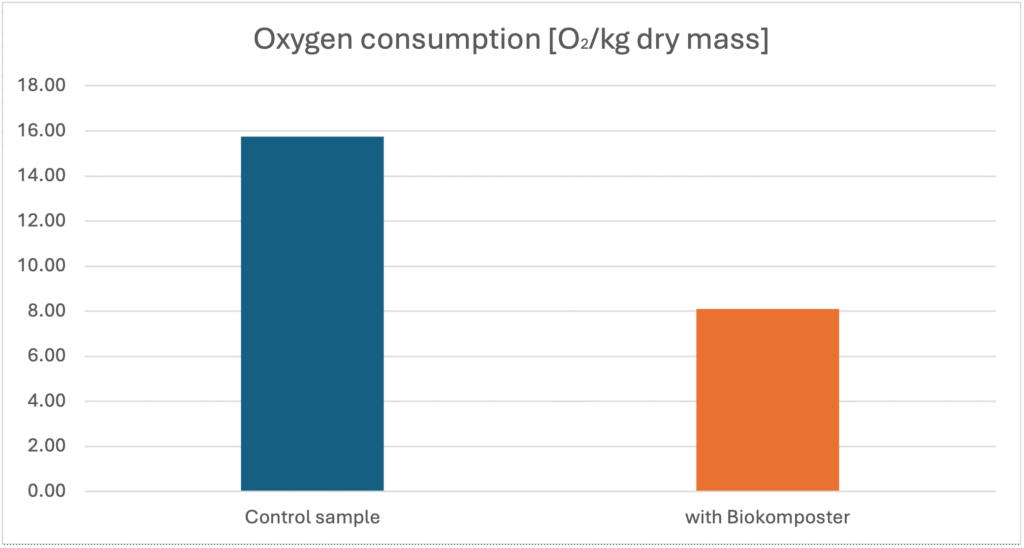

Across 20 weeks, the team composted outdoors. Meanwhile, they tracked progress with the AT4 test, which measures oxygen consumption over four days. Importantly, a lower AT4 indicates more stable, mature compost. Therefore, falling AT4 values over time signal faster biodegradation and better compost quality. Ultimately, this metric offers a clear, comparable indicator of maturity between treatments.

Results: clear improvement with Biokomposter

- AT4 per fresh mass: 5.43 O₂/kg (control) vs. 3.57 O₂/kg with Biokomposter — a reduction of about 34%.

- AT4 per dry mass: 15.74 O₂/kg (control) vs. 8.10 O₂/kg with Biokomposter — a reduction of about 49%.

| Oxygen consumption [O2/kg fresh mass] | Oxygen consumption [O2/kg dry mass] | |

| Control sample | 5.43 | 15.74 |

| with Biokomposter | 3.57 | 8.10 |

This shows the treated pile was significantly more stable, with fewer easily degradable organic substances remaining.

Maturity metric (AT4): Oxygen consumption; lower AT4 = more mature/stable compost

Visual differences

Alongside the data, visual checks supported the findings:

- Control pile: poorly composted, with undecomposed leaf laminae still visible.

- Biokomposter pile: well-mineralised, with mainly tough hop stems remaining — clear evidence of deeper breakdown.

Visual check: The treated pile showed well-mineralised material; mainly tougher hop stems remained, while the control still had poorly decomposed leaf laminae.

Photo 1. Control sample – poorly composted organic matter is visible. Fragments of undecomposed leaf laminae can be seen.

Photo 2. Sample treated with Biokomposter – very well-mineralised organic matter is visible, with mainly tough hop stems remaining.

What this means for growers

For farmers and growers working with fibrous, high-lignin residues such as hops, Biokomposter delivers:

- Cleaner handling and predictable nutrient return – as a result, you support regenerative goals while planning applications with confidence.

- Faster, more complete stabilisation – in fact, AT4 drops to nearly half on a dry-matter basis, so piles mature sooner.

- Field-ready compost on schedule – therefore, you cut the risk of spreading immature compost that can scorch crops or stall growth.

Conclusion

In short, composting hop residues with Biokomposter accelerates decomposition and biodegradation, producing more mature, stable compost within the same 20-week period. Because the preparation supports the right microbial environment – balanced carbon, nitrogen, moisture, and oxygen – it turns challenging residues into high-quality compost and, ultimately, humus that enriches soil health.

Finally, if you want to make composting more efficient, check our website for Biokomposter and other microbial products designed to support your needs.