If slurry tank foaming and crust keep turning agitation day into a slog, you’re not alone. With the right biology, tanks liquefy faster, foam drops, odours ease and pumping becomes predictable, so you can get on with the job.

If this sounds familiar, you’re in the right place

Before finding us, most farmers tell us they feel…

- Dread on “agitation day” because it always takes longer than planned.

- Frustration burning PTO hours and diesel just to get slurry moving.

- Embarrassment or stress after odour complaints from neighbours.

- Pressure from tight spreading windows and compliance checks.

Meanwhile the store keeps crusting, foam steals headroom, and pumping is unpredictable. You’re firefighting, not farming.

The real problem (and what happens if you ignore it)

Symptoms you can see:

A stubborn crust and settled solids that never truly mix.

Sudden foam surges during agitation.

Striping and poor spread patterns in the field.

If you try to “power through” without fixing the cause:

Lost time & fuel: more minutes to reach a full mix; extra PTO hours.

Safety risks: unstable foam, blocked pipes, messy blow-outs.

Odour spikes: complaints and reputational damage locally.

“Disappearing” capacity: foam eats headroom so stores brim earlier.

Compressed operations: narrower legal windows; rising compliance stress.

The fix: biology that liquefies and calms

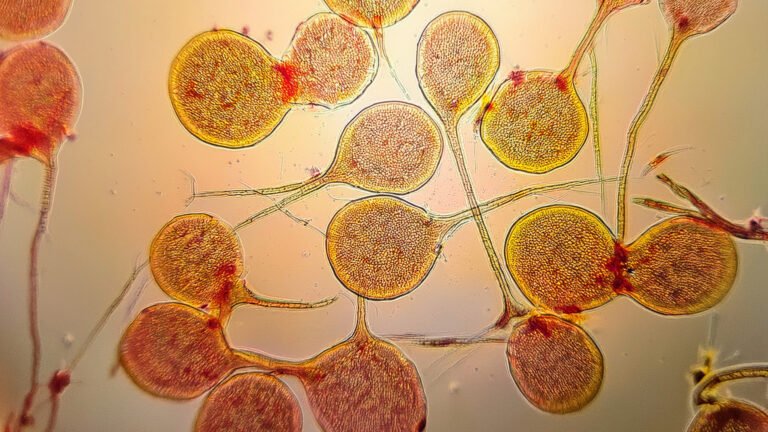

Crusts and foam are symptoms of incomplete breakdown. Targeted microbes (carefully selected Bacillus consortia) digest the organics that form crusts and settled layers. As solids break down, slurry becomes uniform and pumpable. At the same time, biological activity helps stabilise foam, so agitation is quicker, safer and more predictable.

What this looks like on farm

- Faster pull-through once stirrers go in.

- Lower, steadier foam during agitation.

- Cleaner fan pattern and fewer surprises in the pipe.

- Tangible practical capacity gained as the store behaves.

Slurry tank foaming – Simple protocol (reset → maintain)

1) Reset problem tanks

- Dose Agro SanitoBac STARTER after drawing down to expose more surface.

- Mix with water per label and distribute across the tank surface or via agitation points.

2) Maintain flow and foam control

- Apply Agro SanitoBac CONTINUER monthly to keep solids in suspension and odour lower.

- Small, regular doses beat occasional “shock” treatments.

3) Practical dosing tips

- Dose by tank volume (rule of thumb: one STARTER sachet covers ~100 m³; always check the label).

- Avoid bactericides/disinfectants close to dosing.

- Keep a simple tank log (date, dose, agitation minutes, observations) to track progress and support audits.

Expected improvements (what farmers usually report)

- Agitation time ↓ – less time to reach a full uniform mix.

- PTO hours & diesel ↓ – shorter, cleaner runs.

- Spreadability ↑ – more even, predictable patterns.

- Odour spikes ↓ – calmer days on the lane and fewer complaints.

- Capacity ↑ – less “lost” headroom to foam and crust.

Every store is different; run a 6–8 week baseline with a simple log to quantify gains.

Field tips: do’s & don’ts

Do

- Apply at several points around the store if possible, coverage matters.

- Agitate after the label’s activation period.

- Keep routine monthly maintenance, consistency prevents re-crusting.

Don’t

- Combine close to caustic cleaners or harsh oxidisers.

- Skip months and expect the same result next time.

- Assume “more is better”, follow the rate for your volume.

The science behind BactoTech’s slurry products

- Agro SanitoBac STARTER – kick-starts liquefaction in heavy, crusted tanks to make initial agitation safer and faster.

- Agro SanitoBac CONTINUER – monthly maintenance dosing to keep slurry flowable, odour lower and solids in suspension between draws.

Compatibility & safety: These microbiological formulations are designed for slurry systems and normal farm handling. Always follow the product label and safety data. Avoid tank-mixes with bactericides close to dosing.

What to measure (so it’s evidence, not “feel”)

Track five simple things in your log (photos help):

- Agitation minutes to reach full mix.

- PTO hours / diesel used on agitation day.

- Foam height at start/mid/end of agitation.

- Spread pattern (notes or quick photos).

- Incidents/complaints (target = zero).

FAQs

Will this replace agitation?

No. You’ll still agitate, but with liquefaction you typically need less time to achieve a consistent mix.

Can I dose in winter?

Yes. Activity is slower in cold weather, but you still gain from ongoing liquefaction and foam control.

How soon will I see a difference?

Badly crusted stores often improve after the reset application; predictable monthly maintenance keeps them behaving.

Is it safe around stock and staff?

Use as directed on the label and follow the safety data sheet. Designed for use in agricultural slurry systems.

What if I recently disinfected the shed?

Leave a buffer before/after dosing. Harsh disinfectants can knock back beneficial microbes. Check the product guidance for timings.

Ready to stop slurry tank foaming and crust?

Tell us your tank dimensions, current agitation time and any foam/odour issues. We’ll send a tank-by-tank dosing plan and a one-page log sheet you can start using this week.

→ Get your plan: Contact BactoTech UK

→ Learn more: Agro SanitoBac STARTER · Agro SanitoBac CONTINUER – HERE and here: SLURRY STORE FULL, SLURRY ODOUR COMPLAINTS

Editorial note: This article provides general guidance. Always follow your product label and local regulations. Last updated: September 2025.