If slurry odour complaints keep flaring up and NVZ inspections hover in the diary, you’re not alone. However, you don’t need to reinvent your whole system. By calming foam and evening out slurry, you can reduce smell incidents, spread more consistently, and keep a clean paper trail that stands up to checks.

In England, councils must investigate odour complaints that could be a statutory nuisance, and the Environment Agency enforces the Farming Rules for Water; NVZs add specific recording and storage duties. Consequently, predictable behaviour and tidy logs matter.

Make Spreading Days Boring Again

Quiet lanes and tidy logs beat firefighting; fix the breakdown biology so the job becomes predictable.

If this sounds familiar, you’re in the right place

Before finding us, many farms feel on edge about inspections and paperwork being “not quite right.” Moreover, odour spikes on spreading days are embarrassing, especially when the lane gets busy. Meanwhile, striping, blockages and inconsistent patterns waste time and nutrients, and short legal windows rarely match the weather.

Consequently, slurry stays foamy and unpredictable. Records take ages, and every spreading day feels like a risk.

Where farms get tripped up (and what happens if you ignore it)

Common pitfalls

- Foamy, stratified slurry → uneven nutrient delivery and striping.

- Odour spikes on the lane → neighbour complaints and reputational damage.

- Messy logs → hard-to-defend records when an inspector asks.

If you try to “get through it” without fixing the cause

- Higher compliance risk and more stressful audits.

- Unpredictable spreading → wasted time and wasted N.

- Neighbour friction that lingers after the tractor’s parked.

- Narrower operating windows as you juggle weather and admin.

Remember, NVZ rules set out extra storage and record-keeping requirements; having a standard routine and consistent logs makes inspections far calmer.

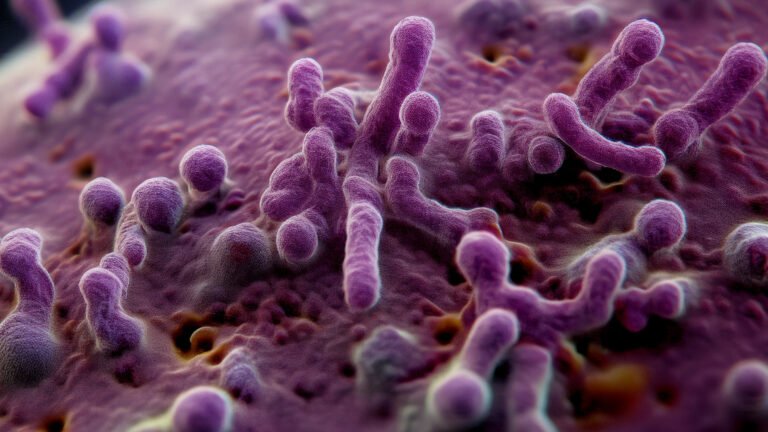

The fix: biology that evens out slurry and calms smell

Crust and foam are symptoms of incomplete breakdown. Therefore, targeted microbes (selected Bacillus consortia) digest the organics that form crusts and settled layers. As solids break down, slurry re-suspends and behaves consistently. At the same time, biological activity helps stabilise foam and reduce odour spikes, so spreading is smoother and records reflect a repeatable process.

On farm, this looks like

- Cleaner fan patterns and fewer blockages.

- Lower, steadier foam during agitation and loading.

- Fewer smell incidents, and calmer conversations with neighbours.

- Simpler, more defensible logs because your routine is consistent.

Simple protocol (reset → maintain)

1) Consistent maintenance dosing

First, reset stubborn stores with Agro SanitoBac STARTER after drawdown. Then keep behaviour predictable with Agro SanitoBac CONTINUER monthly.

2) One-page protocol + tank notes

Next, write your routine once (dose, timing, checks), and keep it on the wall. After that, log date, product, volume treated, agitation minutes and observations every month.

3) Standardise rate and checks

Finally, dose by volume (rule of thumb: one STARTER sachet ≈ 100 m³; check the label). Avoid bactericides/disinfectants close to dosing. Use the same pre-spread checks each time (foam level, mix quality, nozzle pattern).

What improves (typical on-farm outcomes)

- Spreadability ↑ – more even nutrient delivery, less striping.

- Odour spikes ↓ – calmer yards and fewer complaints.

- Agitation minutes ↓ – quicker to a uniform mix.

- Record quality ↑ – a consistent routine that’s easy to evidence.

Because every store differs, track a 6–8 week baseline so gains are obvious when inspectors, or you, ask.

Record-keeping made simpler (copy/paste this routine)

Protocol title: Slurry Liquefaction & Odour Control – Monthly Routine

Steps:

- Inspect store (foam height, freeboard, crust presence).

- Dose per label (STARTER after drawdown as needed; CONTINUER monthly).

- Wait activation period → agitate to uniform mix.

- Record: date, product & rate, store volume treated, agitation minutes, comments (odour, foam, spread pattern).

- File photos of foam height and spread pattern 2–3× per season.

Councils investigate odour complaints under statutory nuisance rules, so these photos and notes help show due care. GOV.UK

(Ask us for our one-page NVZ/FRfW log template—free.)

Field tips (to keep inspections calm)

Do

- Dose from multiple points if possible for coverage.

- Keep monthly maintenance, consistency prevents re-crusting.

- Photograph before/after foam height a few times each season.

Don’t

- Dose right before/after harsh disinfectants or oxidisers.

- Skip logs, evidence is your friend.

- Change nozzles or rates mid-field without noting it.

The science behind BactoTech’s slurry products

- Agro SanitoBac STARTER – resets problem stores by kick-starting liquefaction in heavy, crusted tanks and helping bring foam/odour under control.

- Agro SanitoBac CONTINUER – routine monthly doses to keep slurry moving evenly with lower foam and odour.

Compatibility & safety: Designed for agricultural slurry systems. Always follow the label and safety data; moreover, avoid close sequencing with bactericides.

What to measure (turn “feel” into proof)

- Foam height (start/mid/end of agitation; quick photos).

- Agitation time to reach full mix (minutes).

- Spread pattern (notes/pics of fan uniformity).

- Complaints/incidents (target: zero).

- Log completeness (monthly checks all present).

Slurry odour complaints – FAQs

Will this make me compliant by itself?

No single product guarantees compliance. Nevertheless, predictable slurry behaviour and clean logs make compliance easier to achieve and evidence under FRfW/NVZ frameworks.

Can I use it year-round?

Yes. Activity slows in cold weather; however, you still gain from ongoing liquefaction and foam control.

We have sand/grit build-up – will microbes fix that?

They digest organics. Therefore, sand/grit still needs mechanical management; biology helps keep organics in suspension above it.

How fast does odour improve?

Badly crusted stores often improve after the reset application; subsequently, maintenance dosing keeps peaks down.

Ready to reduce slurry odour complaints and pass inspections with less stress?

Tell us your store volume, current routine and the issues you’re facing. We’ll send a simple protocol, a dosing plan, and our one-page NVZ/FRfW log template so you can show evidence with confidence.

→ Get your plan: Contact BactoTech UK

→ Learn more: Agro SanitoBac STARTER & CONTINUER and also here: SLURRY STORE FULL, SLURRY TANK FOAMING and: MANAGING SLURRY AND MANURE

Editorial note: This article provides general guidance. Always follow your product labels and local regulations. Last updated: September 2025.